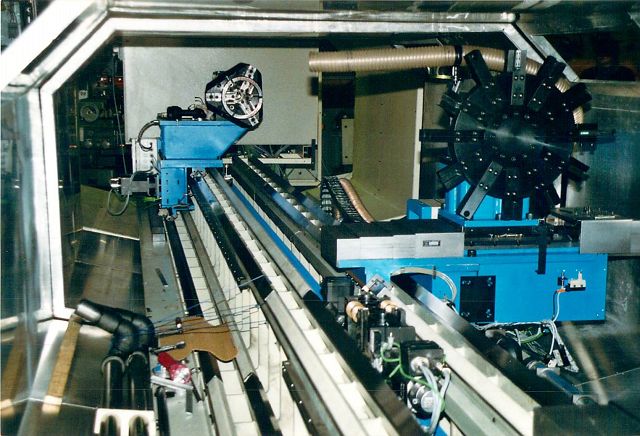

CNC Horizontal bed 10 axes

8 guideways CNC Lathe

WIAP DM2 XA for machining length 7000 mm plastic pipes for power plants

made in switzerland

P1a: The WIAP DM2 XA machine is a special version with 8 tracks. 4 carriages which can drive past without collision. Detail link to the turning machine DM2_XA

P1b. The welded antivibration machine bed by the VDSF process.

P2a. Thousands such pipes should be turned in. Insulators.

P3a. And here this WIAP XA_SM special saw - machine.

P3b. Automatic saw WIAP XA_SM editing system.

P5a. The WIAP XA_FPL gantry. View from above.

P5b. Area gantry. View from the side.

P5c. Presentation Meeting.

P5d. The gripper, which can transport up to 7 meters long pipes.

P5e. With the plant can also conical tubes be processed.

P6. The unique measuring machine WIAP XA_MM.

P7a. Transport of WIAP DM2 XA 8 guide - tracks machine.

P7b. Loading on the truck. |

The WIAP DM2 XA is a robust flatbed CNC lathe. She has a medium wide

bed. Outside the guide clearance is 800 mm. The machine base is a welded

construction. The bed is vibration

relaxed and then filled with the filler WIAP and compacted by

vibration, in accordance with the

Patent of WIAP. The guides X and Z are 50x50 mm. The guides are interchangeable because screwed. For a revision after 20 years suitable, without the bed must return to the supplier. The hardened guides min. 60 HRC are screwed. The slide guides in the X and Z axis are coated with a sliding coating. All axes have air support, that the carriage runs better, does not reach the dirt under the guides and the wear decreased by the multiple, compared with other guides. Lubrication is designed for short path, ie sufficient lubrication for a thread factory. The machine structure is designed such that it can only be transported with minimal disassembly also by land. Delivery dates are short with the Wiap. Mainly because the vibration relaxation MEMV - VSR and the vibration dampening VDSF method is a core piece of a Wiap machine tool, the machine bed can be ready within 6 weeks for assembly. Ask us, we will be glad to give you further information.

1.27

General technical specifications - Swing diameter mm 800 - Rotating diameter mm 620 - Max. Workpiece length to be machined mm 7000 - Travel distance X-axis mm 350 - Travel distance Z-axis mm 7200 - Max. rotating diameter mm 850 - Max. turning length mm 7000 - Lining diameter mm 400, 2x

Main spindle 1 and 2, No. 1 driven Rotations Revol. 100-1000

- Speed,

Change of belt pulley - Spindle bore - Drive power KW 10 but can be adjusted again

- Both spindle blocks can be moved longitudinally; centering with left and right spindle

Clamping device / tensioning device - 2 x 400 mm chuck, fixed to the base jaws with quick exchangeable, replaceable jaws, for the clamping diameters 93 to 610 mm. With 2 cylinders with control. The workpiece is designed for an internal pressure of max. 6 bar

- For each workpiece diameter, 2 sets of 3 pieces each are supplied; designed for use in 3 undercups. - 2 sets of jaws for machining your parts Pos. 4 + Pos. 9.

- Assortment tools for your processing; Incl. Tool holder.

Machine bed - Guids HRC 50 (60) - Bedding width mm inside mm outside - Leadership dimension mm 40 x 40 - Bed length approx. mm 11'000 Travel distance mm 7000

- Spindle center from ground approx. mm 1100

Axes - 2 x X Axis

- 2 x Z Axis

- 2 x height adjustment prism left / resp. right - 2 x spindle head axis

Tool turret

Height

adjustable workpiece prisms

Suction Lathing machine 2 suction Ø 60

Second

headstock instead of tailstock - Length mm 14'000 - Bright mm 2100 - High mm 2000 - Weight kg 6000

Full

coverage

It requires about 1 meter of GRP pipe length per 100,000.- volts

| |